Comprehensive Cane Sugar Processing Chemicals: From Start to Finish

Comprehensive Cane Sugar Processing Chemicals: From Start to Finish

Blog Article

Unleash the Possible of Your Workflow With Proven Walking Stick Sugar Handling Chemical Formulations

In the realm of cane sugar processing, the mission for operational quality is a consistent pursuit - Cane Sugar Processing Chemicals. The use of tested chemical solutions has actually become an essential element in optimizing manufacturing processes and boosting total efficiency. By integrating these formulas into your operations, a range of advantages waits for, promising boosted returns, enhanced pureness levels, and structured procedures that line up with your tactical goals. As the industry progresses, remaining abreast of these improvements can be the separating variable that moves your procedures to brand-new heights of success.

Enhancing Production Efficiency

To optimize manufacturing effectiveness in walking stick sugar processing, it is critical to improve functional processes and adopt innovative innovations where applicable. By implementing reliable functional procedures, such as automating hands-on jobs and using data-driven insights, sugar handling plants can substantially boost their productivity levels.

Furthermore, incorporating advanced modern technologies like expert system and machine discovering can further reinvent the cane sugar processing industry. These innovations can examine large amounts of data to optimize process parameters, anticipate equipment upkeep needs, and improve general plant performance. By embracing automation and digitalization, sugar handling facilities can run with greater precision and dependability, inevitably causing increased production outcome and enhanced item quality. In significance, the search of production effectiveness via structured procedures and cutting-edge modern technologies is extremely important for the sustainable growth and competitiveness of walking cane sugar processing procedures.

Taking Full Advantage Of Yields and Pureness

Efficiently making best use of yields and maintaining high pureness degrees are crucial objectives in the cane sugar processing industry. Accomplishing optimum yields while maintaining rigorous purity standards calls for a calculated strategy that incorporates innovative chemical formulations right into the processing process. By employing specialized chemicals developed to boost extraction effectiveness, clear up the juice, and boost condensation procedures, sugar mills can substantially enhance their general returns and pureness degrees.

Improving Refine Optimization

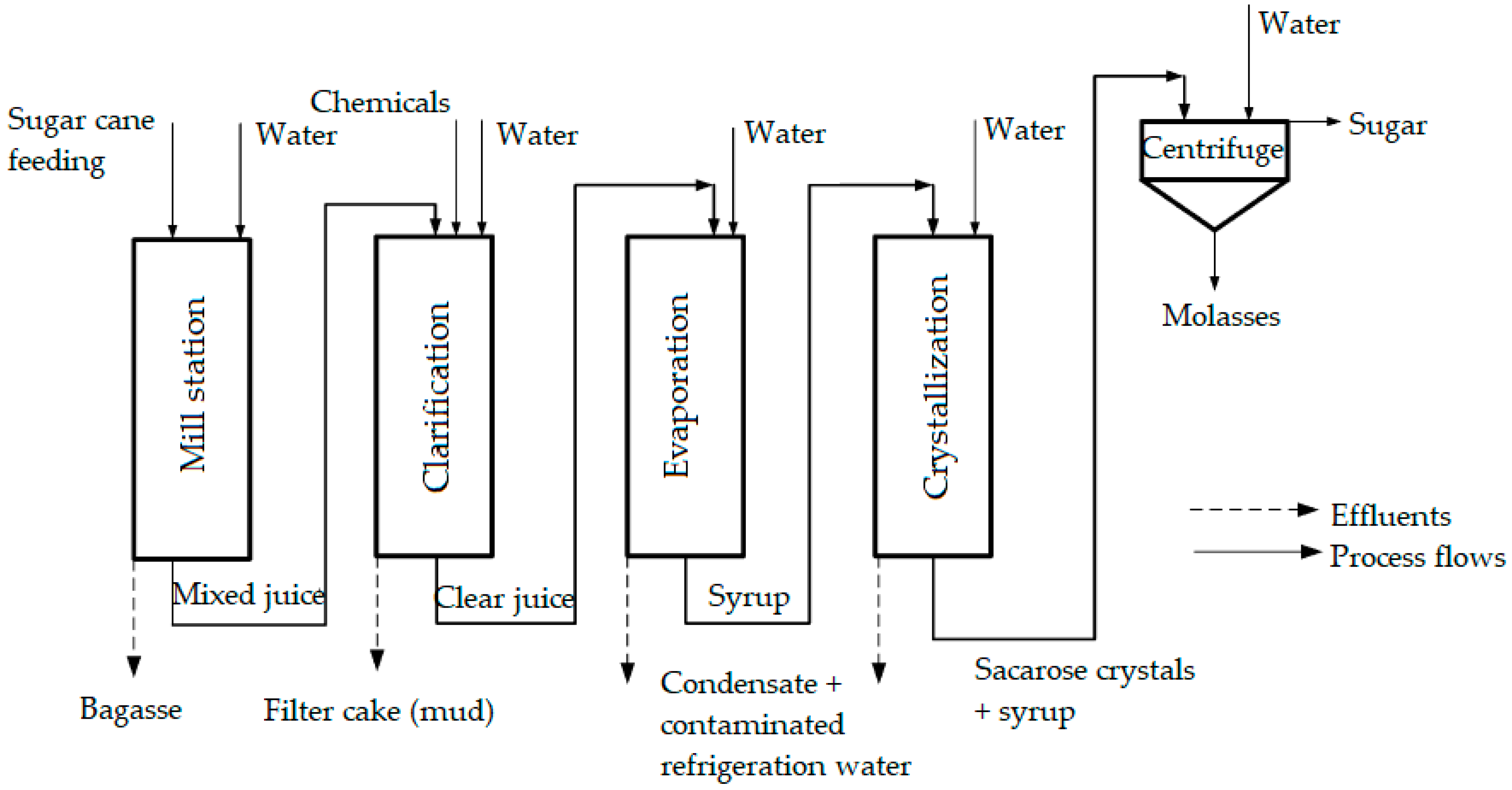

In the realm of cane sugar processing, enhancing process optimization is critical for accomplishing the desired yields and pureness degrees while incorporating sophisticated chemical formulas for boosted performance. Refine optimization involves fine-tuning numerous stages of sugar manufacturing to make the most click now of output while preserving premium quality. One key facet of boosting process optimization is the cautious calibration of tools such as evaporators, crystallizers, and centrifuges to ensure they run at peak efficiency degrees. Additionally, implementing automation and surveillance systems can help recognize traffic jams or inefficiencies in real-time, permitting for prompt changes to boost overall efficiency. Regular maintenance timetables and thorough cleaning procedures additionally play a vital function in keeping the processing plant running efficiently and avoiding unanticipated downtime. By constantly assessing and enhancing each action of the sugar manufacturing process, operators can streamline operations, reduce power usage, reduce waste, and ultimately increase profitability. Embracing procedure optimization as a core principle can bring about lasting renovations in performance and item quality within the walking cane sugar processing market.

Getting Operational Goals Properly

With a strategic concentrate on functional quality, the sugar handling market aims to efficiently meet its production targets and quality standards. Achieving functional objectives effectively calls for a combination of aspects such as structured processes, progressed technologies, and enhanced chemical solutions. By ensuring that each step Bonuses of the sugar processing procedure is very carefully planned and carried out, companies can boost performance and efficiency.

One trick facet of attaining functional goals is the option of top quality walking stick sugar processing chemical formulas. These solutions play an essential role in different stages of the manufacturing procedure, including removal, filtration, and condensation. By utilizing proven chemical solutions particularly created for cane sugar processing, companies can enhance yield, minimize handling time, and enhance the total high quality of the end product.

Furthermore, efficient interaction and collaboration amongst different divisions within the company are essential for lining up functional goals and making certain smooth workflow - Cane Sugar Processing Chemicals. Regular performance examinations, continuous training programs, and data-driven decision-making processes can further support the success of functional excellence in the sugar processing industry. By carrying out these approaches, companies can let loose the complete possibility of their operations and stay ahead in an affordable market

Enhancing Output Top Quality

Additionally, boosting output quality likewise requires continual surveillance and adjustment of handling parameters to preserve consistency and satisfy quality requirements. Quality control actions such as regular screening for pureness, dampness material, and granulation make sure that completion product satisfies market criteria and customer expectations. By spending in the appropriate chemical solutions and prioritizing high quality throughout the manufacturing process, sugar processing facilities can achieve premium final result quality that establishes them apart out there.

Verdict

Finally, see this site using tested walking cane sugar processing chemical formulas can substantially boost production efficiency, maximize returns and pureness, enhance process optimization, achieve operational goals effectively, and improve end product quality (Cane Sugar Processing Chemicals). By integrating these solutions into procedures, companies can unlock the full possibility of their sugar handling facilities and guarantee an extra structured and effective production procedure

Report this page